How Balloons are Made

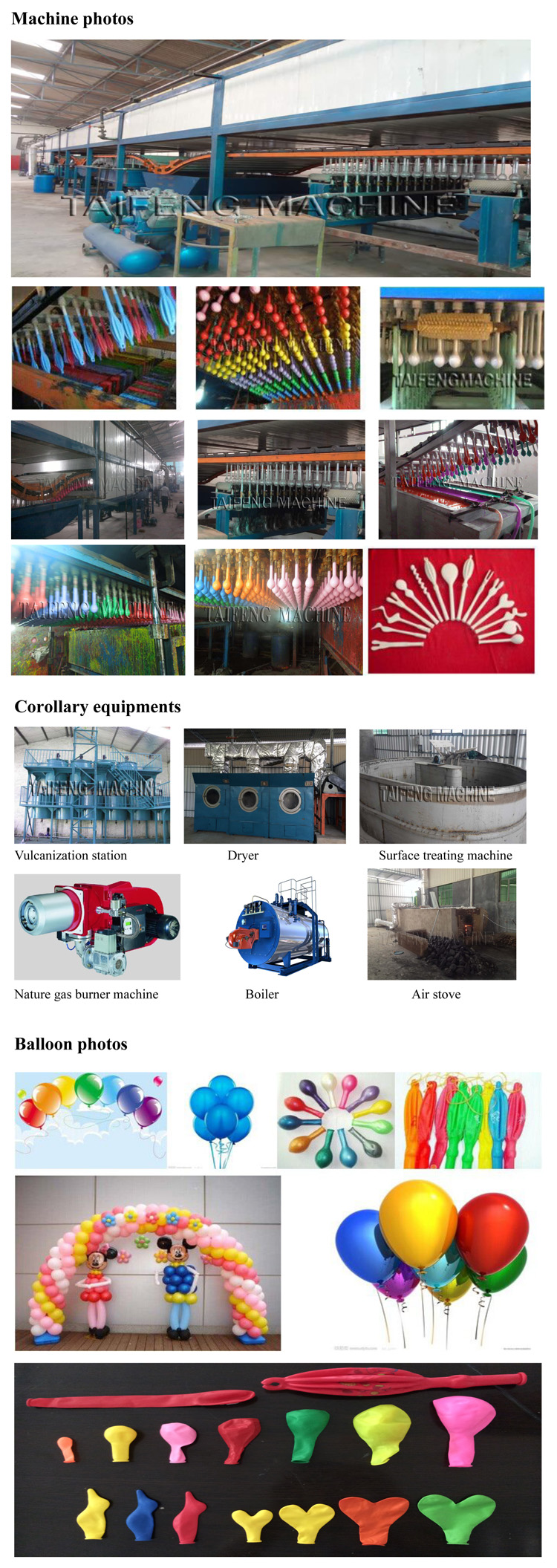

Blloons are manufactured from a liquid rubber called natural latex. And the balloon gets its color from the pigment that is added to the latex than mixed in the mixing plant.

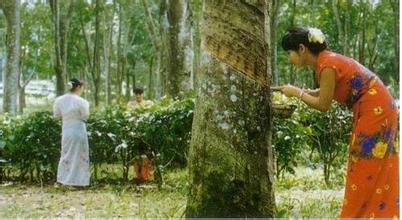

The natural rubber latex that we use comes from the sap of the rubber tree , that grows in Malaysia or Thailand,etc. This sap looks like milk and is shipped to all over the world in large ocean tanker ships. Once removed from the tree, the sap is called latex. To make this suitable for balloon production, curing agents, accelerators, oil, color, and water must be added. After these are added, the completed latex is put in an open tank, then the latex can be use to dip into the balloon. Before the form is dipped into latex, it is dipped into a coagulent that causes the rubber particles of the latex to collect on the form. This coagulent is calcium nitrate, water, and/or alcohol. After the coagulent coated form is dried, it is then dipped into the compounded latex. Then the latex coated form passed through a set of revolving brushes that rolls the balloon neck into the bead that is used to aid in the inflation of the balloon. The latex coated form is then washed in hot water to remove any unused nitrate. Following the leaching, the form is put in a 120-160 degrees temperature oven to cure for 20-25 minutes.

The above are controlled by: surface tension control of coagulant and good antisettling of 'chalk', even speed immersion and withdrawal with still liquid surface, correct compound viscosity and correct chemical stability, clean formers and efficient filters good step back of film thickness, well-leached film, and dryness state chemically friendly formula.

And even latex film depends upon a consistent coagulant deposit. This, in turn, depends upon a fast drying time and an even speed of withdrawal from the coagulant (which implies a hot coagulant and former). With small time cycles leading up to the coagulant dip, it is important not to lose heat necessarily after the stripping.

The following questions apply to the manufacturing of latex balloons.

Q: How much does a typical balloon cost to produce?

A: Each balloon size and type will have a different cost. It's a combination of the amount of latex used, and how easy it is to automate the process.

Q: Is the balloon manufacturing process all automated?

A: It is largely automated these days.

Q: After the molds are dipped into the latex, how does the balloon come off its mold? (manual removal or automated process?)

A: It depends on the size and shape of balloon. Some are completely automated. Some are stripped manually (with the help of forced air/water on the form).

Q: This question may sound weird, but can you bond/fuse two balloons together, or say, two dried strips of latex together?

A: This is getting into an area I know less about. I can tell you from experience that balloons can stick together if heat is applied, but they dont' hold together very well and can be pulled apart. During manufacture, if you stick them together prior to curing them, they will fuse. This is what happens with the 6-inch hearts and 260's that are stuck together at the tips. the forms are too close together on the racks that get dipped, so after dipping, they sometimes touch each other and join.

- Pre:latex shoe set formulation pro 2015/8/29

- Next:Characteristics of medical exa 2014/5/25